When it comes to building insulation, choosing without clear criteria is not enough. The Spanish Building Code (CTE) sets out the requirements for thermal insulation: documented quality, certified technical performance, and suitability for real construction conditions.

1. Quality requirements for thermal insulation materials

Part I of the Spanish Building Code (CTE) states that buildings must meet the basic requirements of ‘energy saving and thermal insulation’, and that these requirements must be ensured throughout all phases: design, construction, maintenance, and use of the building.

Article 7, Conditions for the execution of works, in section 7.2, sets out the conditions for on-site acceptance control of products, equipment, and systems. The aim is to verify that they comply with the project specifications. This involves (1) checking the supply documentation, (2) control through quality marks or technical assessments of fitness for use, and (3) control through testing. In short, suppliers must at least provide the following documentation:

- origin documents, delivery note, and labelling;

- the manufacturer’s warranty certificate, signed by an authorised person;

- the conformity documents or regulatory administrative authorisations required by law, including the CE marking of construction products;

- quality marks ensuring the technical characteristics;

- technical assessments of fitness for the intended use.

Article 7 clearly specifies that the “construction works director” shall verify that the documentation is sufficient for the acceptance of products, equipment, and systems.

The CE marking of thermal insulation products, as with all other construction materials, is currently regulated by the Construction Products Regulation (EU) 305/2011, which replaced the former Construction Products Directive 89/106/EEC. This regulation requires manufacturers to issue a Declaration of Performance (DoP) and ensures that the declared performance is assessed using harmonised methods throughout the European Union. Therefore, in the case of thermal insulation products, the documentation to be provided by the supplier at the time of on-site acceptance must include:

- Technical data sheet with declared values: declared thermal conductivity, thickness, declared thermal resistance, etc.

- When the family of thermal insulation materials has a European harmonised standard: CE marking and Declaration of Performance (DoP). The families that currently have such a harmonised standard are:

| Abbr. | Thermal insulation material | Standar |

|---|---|---|

| PE | In-situ expanded perlite | EN 14316-1 |

| EV | In-situ exfoliated vermiculite | EN 14317-1 |

| MW | Mineral wool | EN 13162 |

| EPS | Expanded polystyrene | EN 13163 |

| XPS | Extruded polystyrene | EN 13164 |

| PUR/PIR | Rigid polyurethane/polyisocyanurate boards (not sprayed) | EN 13165 |

| PF | Phenolic foam | EN 13166 |

| CG | Cellular glass | EN 13167 |

| WW | Wood wool | EN 13168 |

| EPB | Expanded perlite boards | EN 13169 |

| ICB | Expanded cork boards | EN 13170 |

| WF | Wood fibre | EN 13171 |

| PUR | Sprayed rigid polyurethane foam system | EN 14315 |

| ETICS EPS | External thermal insulation composite system (ETICS) with EPS | EN 13499 |

| ETICS MW | External thermal insulation composite system (ETICS) with mineral wool | EN 13500 |

| Mineral wool thermal insulation products for industrial applications – equipment | EN 14303 | |

| LFCI | In-situ formed cellulose insulation products | EN 15101-1 and EN 15101-2 |

- When the family of thermal insulation materials does not have a harmonised European standard, the manufacturer must obtain an ETA (European Technical Assessment), which allows them to issue the Declaration of Performance (DoP) and affix the CE marking. This is the case for reflective insulation, straw bales, animal wool, and similar products. The manufacturer must apply for the ETA through an authorised body (EOTA) via a notified laboratory (Technical Assessment Bodies TABs), such as the Eduardo Torroja Institute for Construction Science in Spain or the CSTB – Scientific and Technical Center for Building in France.

- Voluntary product certifications such as the AENOR N Mark (Spain) or the French ACERMI certification.

What are the implications if a manufacturer of a construction material without a harmonised standard does not obtain an ETA?

In that case, the manufacturer cannot affix the CE marking and, consequently, in Spain the product would not comply with Part I of the CTE, as the performance of the material could not be officially guaranteed. Legally, it could only be used if the designer and the project management team accept the manufacturer’s data sheet ‘at their own risk’, but in public works and in most cases requiring technical approval, its use would be unfeasible.

Is there a standard to facilitate on-site installation control of thermal insulation materials?

Regarding on-site installation, compliance with UNE standards is required, which regulate how to verify insulation at the different stages (design, installation, final inspection) — for example, UNE 92325:2018, which provides checklists adapted to the type of insulation (EPS, XPS, cellulose, mineral wool, etc.).

Specification of thermal insulation materials in building projects

In the project documentation (report, bill of quantities, drawings, and specifications), it is advisable to detail

- Type of product and applicable EN standard.

- Declared thermal conductivity (λD).

- Planned thickness.

- Declared thermal resistance (RD).

- Additional properties according to the requirements of use: compression strength, water absorption, reaction to fire, etc.

- Documentation to be submitted on site.

Practical examples:

- Double brick ceramic façade: “Expanded polystyrene (EPS) thermal insulation, in accordance with EN 13163, declared thermal conductivity λD = 0,037 W/m·K, thickness 60 mm, declared thermal resistance RD = 1,60 m²·K/W and Euroclase E (reaction to fire). The supplier shall provide on site: Declaration of Performance (DoP), CE marking, and technical data sheet.”

- Inverted roof: “Extruded polystyrene (XPS) thermal insulation, in accordance with EN 13164, declared thermal conductivity λD = 0.034 W/m·K, thickness 80 mm, declared thermal resistance RD = 2.35 m²·K/W, compressive strength ≥ 200 kPa, water absorption by diffusion ≤ 0.7%, and Euroclass E (reaction to fire). The supplier shall provide on site: Declaration of Performance (DoP), CE marking, and technical data sheet.

In more demanding projects that go beyond the Spanish Building Code (CTE)—for example, those including sustainability assessments with VERDE, BREEAM, or LEED systems—the supplier should also provide the Environmental Product Declaration (EPD) used to carry out the Life Cycle Assessment (LCA) of the building design. This may become mandatory in Spain within a few years, once the future Basic Document on sustainability, DB-HSA, comes into force.

2. Performance properties required for the intended application

When selecting a type of thermal insulation material, we might believe that thermal resistance is the only aspect that matters. This would lead us to think that any kind of insulation could be used in any application (type of construction solution) and that the only adjustment required would be to increase or decrease the thickness depending on its thermal conductivity, in order to achieve the same thermal resistance value.

In reality, the choice of the type of insulation material to be used in a construction solution must be based on the required properties according to that specific application. This is what is referred to as the “properties according to the end-use application“. In addition, it is the manufacturer’s responsibility to specify the applications for which the product is marketed.

As a general guideline, the properties to be required depending on the application are:

- Water absorption by immersion and by diffusion: vital in inverted roofs or below-grade walls insulated on the outside.

- Compressive strength (or stress at compression): essential in floors or walkable roofs where the insulation is placed above the slab.

- Tensile strength: required in ETICS systems.

- Dynamic stiffness: in cases where thermal insulation is also used for impact sound insulation.

- In addition, λD, thickness, and RD must always be considered to ensure energy efficiency and comfort.

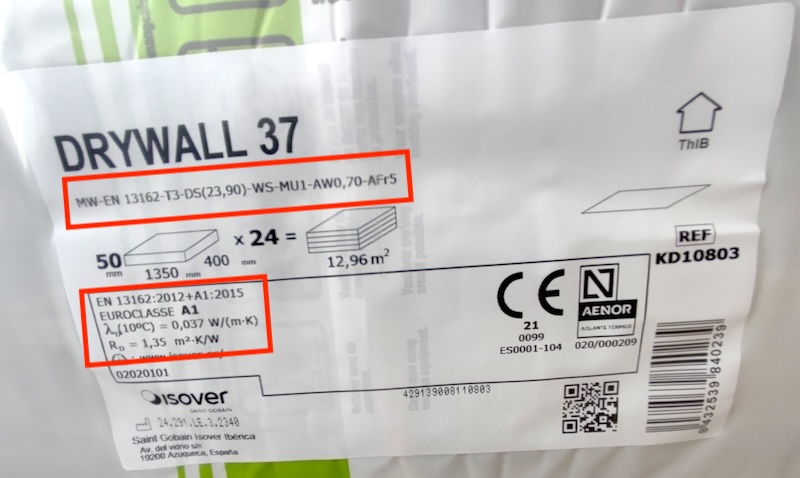

All these properties are included in the ‘designation code’ that the manufacturer places on the product package label, similar to what is shown in the following image:

3. Final recommendation: documentation consistency from project stage through to on-site execution

Close the loop by ensuring that what is specified in the design is reflected on site. In the building logbook, include copies of the technical data sheet, DoP, certifications, installer’s control, and verification results. This consistency strengthens compliance with the CTE and protects against thermal or legal surprises.

And remember: having an independent technical team is the best guarantee. At ETRES Consultores we provide on-site quality control services for thermal insulation materials and technical advice to ensure compliance with the CTE. A small investment that prevents major problems.